1、Logistics and distribution management system for the present and the future of the complex and changeable automated production line material handling system, automated distribution system provides a complete information management solutions. The system has simple operation, multi language support, parameter configuration, dynamic plug-in expansion and other advantages, provide order processing for the distribution center picking strategy optimization, optimization can improve distribution center picking efficiency.

Through the CMMI3 specification project development life cycle management, guarantee the system stability and high reliability index, meet the system for a long time without interruption. The current logistics management system includes distribution management TARS (automatic replenishment system), TASS (automatic sorting system), and integrated TINF interface module.

2.main function modules

(1) automatic replenishment system (TARS)

The automatic replenishment system is a system between warehouse management system and sorting system in the middle, available inventory and operation of the warehouse management system obtained by real-time system, inventory and sorting ability sorting system, dynamic adjustment of sorting material replenishment plan, to realize the continuous supply of sorting system, guarantee the smooth operation of the sorting system. Through real-time monitoring warehouse, sorting equipment status, the implementation of the task of conveying materials, you can change the delivery strategy in a timely manner.

(2) automated sorting system (TASS)

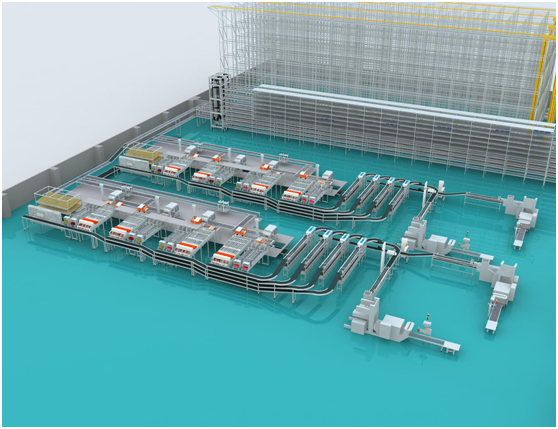

Automatic sorting system is the integrated equipment to meet the needs of diversified distribution center picking a variety of materials, to provide delivery or pick the best path to control the distribution center operation unit real-time beat, the picking process reasonably and orderly. And integrated distribution center diversified storage, transportation, sorting, identification, information presentation and other equipment.

Based on the classification device, control device, conveying device and classification of crossing control, realize the continuous, large quantities of material distribution, can be automatically according to orders, line, area, the second wave picking, and meet the production requirements of very low error rate, and can pick through the real-time state monitoring system to feedback control personnel.

Full application of the Internet of things technology, intelligent control of the distribution center of the business processes, in advance to generate a reasonable scheduling instructions (pre processing technology), and effectively improve the efficiency of operations.

(3) integrated interface module (TINF)

The integration of the information system and the integration of the upper information system is realized through the interface middleware TINF.

3、 system advantages

(1) flexible order optimization strategy

The order system design optimization strategy can be configured according to the needs, can be adjusted flexibly (such as sharing strategy, strategy, strategy of material limited tolerance, etc.) for batch processing, real-time dynamic processing of orders, can effectively improve the efficiency of order picking.

(2) pretreatment strategy

System with intelligent data preprocessing strategy, can be combined with the actual operation of the system, the implementation of the order task data preprocessing, effectively improve the efficiency of the system.

(3) flexibility

Centralized management and decentralized control are adopted to make the system have high flexibility, and the data processing can be distributed flexibly.

|